While using a thermal imager, you may have experienced occasions where it seems like the image on the display freezes for a brief moment before resuming normal operation. This is not a result of “scanning too fast” or “moving too quickly”, as is commonly thought; rather, this a normal part of thermal imager operation and something you should be aware of because if it occurs while you are scanning a room, details could be missed while the image is momentarily frozen. So, why does your thermal imager do this?

This momentary freeze, often referred to as a ‘shutter fire’ or ‘shutter event’, occurs when the thermal imager is performing an internal process known as a Non-Uniformity Correction (NUC). In order to maintain a high-quality image and accurate readings of IR radiation, the imager must accommodate and compensate for a variety of highly dynamic factors such as the increased temperature of the internal electronics, the differing amounts of IR radiation from the environment, and even the increasing temperature of the lens. One of the ways the imager does this is by performing a NUC – a process by which a physical shutter comes down between optic and detector, providing a flat and uniform reference source for the detector to calibrate itself before the shutter opens again. This process is also accompanied by a faint clicking sound and a momentary freezing of the image.

All fire service thermal imagers are equipped with this function which will typically occur when shifting from one gain state to another, as explained below, as well as automatically as needed to help ensure the best image quality and most accurate performance. Differences from one fire service thermal imager to another may be noticed in the following characteristics:

1. Frequency of a NUC

This is how often a NUC must be performed. There are wide variations in the frequency of NUC’s in fire service thermal imagers but you should expect a NUC to occur every 2-3 minutes, depending on manufacturer and conditions. NUC’s also occur more frequently when a thermal imager is first turned on, in some cases occurring every few seconds, until the imager reaches a steady state of operation.

2. Duration of a NUC

When a NUC does occur, how long does it take to complete the process and resume normal operation or, how long is the image frozen? Again there are wide variations in the duration NUC’s in fire service thermal imagers with some being so quick they are nearly imperceptible and others lasting several seconds.

If your department is currently equipped with thermal imagers and you don’t know the frequency or duration of the NUC’s, it is a simple thing to test, measure and include in your training program going forward.

When considering the purchase of new thermal imagers NUC frequency and NUC duration should be carefully evaluated as they differ widely from manufacturer to manufacturer. Various image processing techniques and other compensation can be employed to reduce the frequency of a NUC, both during startup and while operating, as well as the duration of a NUC when they do occur.

SHUTTER AND GAIN

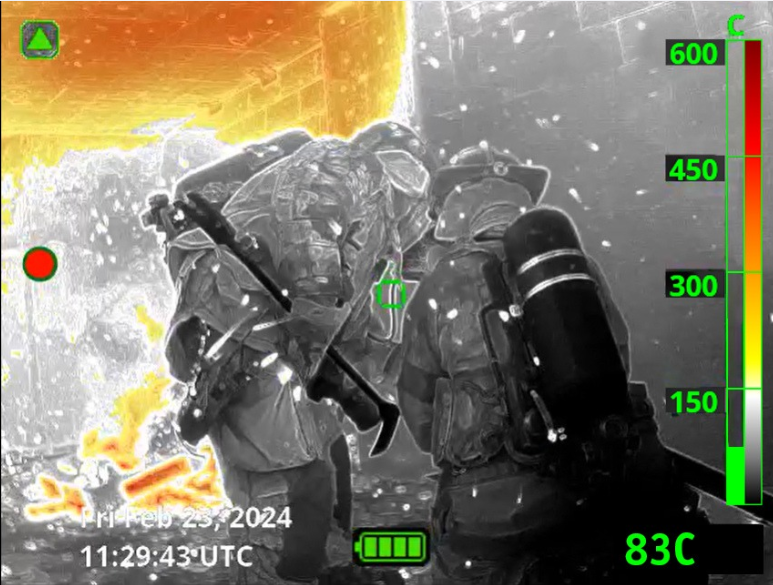

Thermal imagers designed for the fire service are expected to operate across a wide range of temperatures and maintain image quality across all situations. One of the ways this is accomplished is by switching the thermal detector between two sensitivity levels: high gain and low gain.

- High Gain Mode: Used in lower temperature environments, High Gain makes the detector more sensitive to IR radiation which typically provides more detail in the thermal image. This mode is ideal for identifying subtle temperature differences, such as during search and rescue.

- Low Gain Mode: Active for higher temperature environments where IR radiation is both abundant and powerful, Low Gain decreases the detector sensitivity to avoid overloading detector and enabling the imager to process intense heat without the image becoming saturated.

During the transition between these modes, either from high gain to low gain or low gain to high gain, the shutter is often engaged to perform a NUC and calibrate the detector for the change in environment, ensuring the imager adjusts its readings for the new gain setting, producing a smooth, consistent and accurate thermal image.

WHY A SMOOTH TRANSITION MATTERS

Some advanced thermal imagers are designed to make the transition between high gain and low gain nearly seamless. Here’s why this is important:

- Minimized Disruption: A smooth transition prevents the display from freezing or jittering noticeably, which could be distracting or disorienting during critical operations.

- Enhanced Image Accuracy: By calibrating effectively during gain shifts, the imager delivers consistent image quality, ensuring users can trust what they see.

- Improved Situational Awareness: In high-stakes environments, like firefighting, uninterrupted thermal imaging allows responders to focus on their tasks without being hindered by display interruptions.

CONCLUSION

Non-Uniformity Corrections and the associated shutter are integral to the accurate performance and reliable image quality of fire service thermal imagers. These features help ensure the imager provides accurate and reliable information, no matter the temperature range. Imagers that effectively reduce the frequency and duration of NUC’s, reduce the need for shutters and offer smoother gain transitions and reduce operational disruptions, giving firefighters the confidence to act swiftly and safely.

Understanding the function of the shutter and gain modes helps users appreciate the technology that powers their tools, ensuring they’re ready to perform under the most demanding conditions.