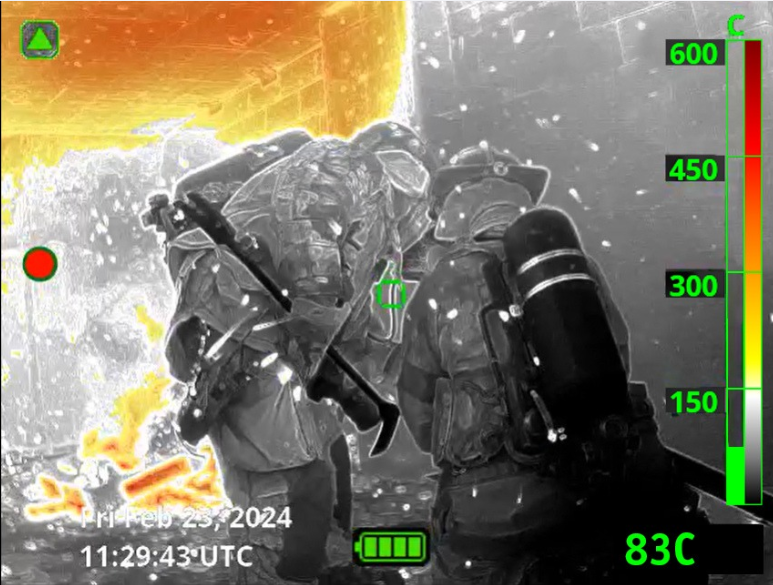

Imagine a world where the details of your surroundings are all blurry, seemingly lost in a haze, where you really have to concentrate to discern what you are seeing and may completely miss details. Your navigation of, and interaction with, this world would be slower, more deliberate, require more attention, and potential place you at greater risk of injury as otherwise minor obstructions like steps or inclined surface might be missed. When it comes to firefighting, these subtle details that could be missed are oftentimes the very details that become cues & clues and form the foundation of situational awareness.

Optics is the branch of physics that studies and deals with light (including visible, ultraviolet, and infrared) — what it is, how it behaves, and how it interacts with matter and plays a crucial role in our daily lives, from the glasses we wear to the cameras we use. We routinely leverage optics in our daily lives to correct or enhance a wide variety of issues to achieve one thing: focus.

Focus refers to the point where incoming rays converge to form a clear and sharp image. When an object is in focus, the details are crisp and well-defined, making it easy to see and understand what you’re looking at, service as the foundation of overall image quality.

Optics and focus in our daily lives is most commonly achieved using elements made of glass; however, as you likely already know, the thermal radiation that is critical to the thermal imager does not penetrate, and is instead reflected by, glass. So how does your thermal imager leverage the field of optics to achieve image quality?

OPTICS CHALLENGES IN THE FIRE ENVIRONMENT

Thermal imaging in general and thermal imaging in the fire service specifically, introduce unique challenges in the world of optics and focus:

Thermal optics cannot be made of glass.

As you likely already know, glass reflects infrared radiation so if thermal optics were made of glass, no infrared radiation would make it to the detector. Instead, thermal optics are made from a variety of materials that are transmissive of infrared radiation.

Ruggedization

The fire service is a unique application when it comes to sensitive electronics. Ruggedization becomes a critical part of the design of any product intended for use in this market. Durable and resilient outer housings, rubber bumpers, internal insulation and heat management, and field replaceable parts all help in this arena.

Austere environment

The firefighting environment is further complicated by high heat environments, wide temperature swings, cold weather usage, and thermal shock exposures, where an imager might become extremely hot from environmental exposure and then be contacted by a hose stream of cold water and then be dropped down a flight of stairs without damaging the optics or disrupting the focus of the imager.

One way in which this level of durability is achieved is by employing two optical elements: one protective and sacrificial, and the other performant and functional.

THE TWO OPTICS IN A THERMAL IMAGER

- The Core Lens

Function: This is the primary element to provide the critical focus needed for excellent image quality. The core lens is part of the thermal sensor array, where incoming infrared radiation is detected and converted into electronic signals.

Role: It determines how the imager captures thermal data, affecting sensitivity and the ability to detect subtle temperature differences.

Key Feature: The core lens’s precision influences spatial resolution, ensuring the imager can distinguish between closely spaced heat sources. In addition, the ability of the core lens to maintain focus over time and under extreme heat conditions is also critical to providing the expected performance and image quality.

- The Germanium Window

Function: The germanium window is the outer optical element, visible directly at the front of the imager, that serves to protect the core lens and the core itself from environmental exposure to heat, water and debris.

Role: The role of the window is to protect and shield the core lens from anything that would interfere with core lens operation and provide a sacrificial layer of protection for scratches, gouges and other damage.

Key Feature: Germanium is used because it is both highly effective at transmitting infrared radiation and highly durable to withstand harsh firefighting environments.

PROTECTING AND MAINTAINING THERMAL OPTICS

Thermal imager optical elements are precise components that require some care to maintain optimal performance. Here are best practices for protecting and maintaining the optics:

- Protecting from Damage

Core Lens:

Internal, but still susceptible to contamination if the imager housing is damaged.

Regularly inspect the imager for cracks or wear that could expose the core lens to debris.

Germanium Window:

Often coated with a thin anti-reflective layer to improve infrared transmission and reduce glare.

Protect this coating by avoiding abrasive cleaning tools or chemicals.

Use a lens cover or protective shield when the imager is not in use.

Regularly inspect for damage and/or dirt or debris buildup.

- Cleaning Best Practices

Use a soft microfiber cloth or lens tissue to gently clean the germanium window.

Avoid using water, as moisture can damage the coating. Use a lens cleaning solution designed for infrared optics if needed.

For stubborn debris, use a blower or canned air to remove particles before wiping.

- Routine Inspections

Inspect windows for scratches, cracks, or smudges that could degrade image quality.

Check that lens covers or imager housings are intact and free from warping or damage.

- Environmental Considerations

Avoid exposing the thermal imager to extreme temperature changes, which could cause lens fogging or damage.

Store the imager in a controlled environment when not in use to prolong lens life.

CONCLUSION

The optical elements in a thermal imager—both the core lens and germanium window—are fundamental to the device’s performance, affecting everything from image clarity to spatial resolution. By understanding their functions and maintaining them properly, your department can help ensure reliable operation in even the harshest conditions.