As experienced firefighters, you understand that durability is not just a feature of your gear, but a critical factor in helping to ensure safety and operational success. The environments you work in are unforgiving, with tools constantly exposed to extreme heat, water, smoke, impacts, and debris. A thermal imager’s durability must mean more than surviving occasional wear and tear. It needs to deliver reliable performance in demanding conditions, time after time.

Here’s a detailed look at what durability means for thermal imagers, practical tips for evaluating equipment, and insights from real-world users to help guide your next purchase.

Here’s what a durable thermal imager should handle:

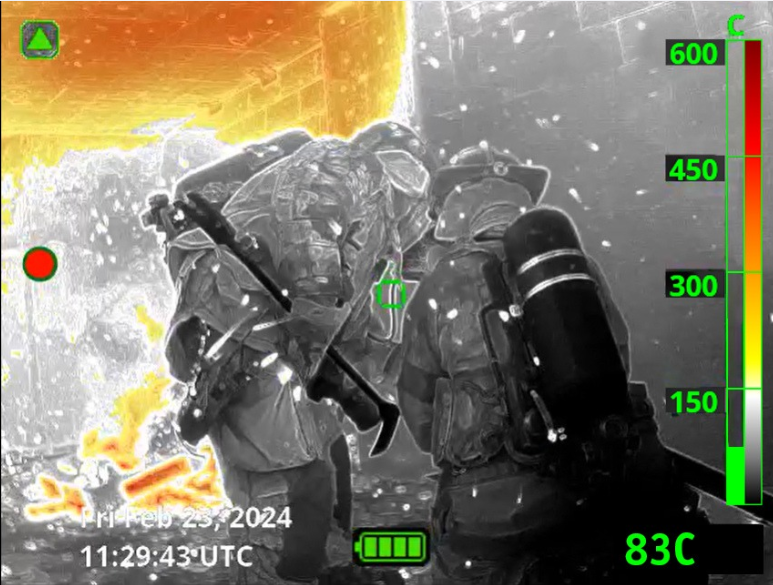

- Heat Resistance: Thermal imagers should function effectively in extreme environments. Models rated to endure short bursts of heat up to or beyond 500°F and maintain continuous operation at 300°F are better suited for fireground conditions. Resistance to brief exposures to direct flame is also critical.

- Water and Dust Protection: Fire scenes are filled with smoke, water, and debris, so it is vital that the imager be both waterproof and dustproof. Devices with a minimum IP67 rating are completely sealed against dust and can withstand immersion in water up to one meter deep.

- Impact Resistance: Drops happen, whether in the heat of action or during routine handling. A thermal imager built with shock-absorbing materials or rubberized housing should survive falls from typical shoulder height without compromising functionality.

- Battery Performance: A reliable battery should last through extended operations without overheating or malfunctioning.

A Firefighter’s Perspective on Durability

To illustrate how these features play out in real-world conditions, consider this scenario shared by a firefighter from a suburban department. During a structure fire, their thermal imager was subjected to intense heat while locating a trapped occupant. Despite being dropped twice onto a concrete floor during the rescue, the imager maintained clear visuals and guided the team to safety. “It’s the kind of reliability we count on,” they explained. Real-world situations like this highlight why durability matters.

Evaluating Manufacturer Claims About Durability

Not all manufacturer claims about durability are equal. Knowing how to evaluate these claims critically can help you avoid disappointment and choose the right tool for your department.

- Look for Objective Testing Standards

Devices should meet recognized durability standards, such as NFPA 1801 for firefighting thermal imagers. These certifications validate a manufacturer’s claims and helps ensure the device has been tested under realistic conditions.

- Request Specific Data, Not Buzzwords

Terms like “rugged” or “built for tough environments” sound good but lack substance. Manufacturers should be able to support “rugged” claims with specifics, such as IP ratings, temperature tolerances, and drop-test results. For example, can the imager survive immersion in water? How high of a drop can it withstand? In addition to providing data, top manufacturers can also demonstrate this durability during demonstrations.

- Real-World Testimonials

Talk to other departments that have used the imager in the field. Hearing how a device performed during extended use or extreme incidents can provide invaluable insights that testing alone may not capture.

- Examine Warranty and Maintenance Programs

A strong warranty shows the manufacturer’s confidence in their product. Additionally, look for preventative maintenance programs or designs with field-replaceable parts. These features reduce downtime and extend the life of the device.

Hands-On Testing Tips

Before purchasing a thermal imager, it’s essential to test it under conditions that mimic the fireground. Here are some practical ways to evaluate a device:

- Demo and Field Testing: Many manufacturers offer live, in person demos. Use these to conduct heat exposure tests, drop tests, and simulated fireground exercises. Involve multiple team members to gather diverse feedback.

- Simulate Extended Use: Keep the imager powered on during drills to observe how it performs over several hours. Check for overheating or excessive battery drain.

- Review Testimonials: Look for reviews or case studies from firefighting professionals. These often highlight how well a device performs in long-term or high-stress scenarios.

Visual Guide: What to Look For in a Durable Thermal Imager

Key Features at a Glance:

- IP Rating: Aim for IP67 or higher.

- Heat Resistance: Operational functionality at 300°F, short bursts up to 500°F.

- Drop Test: Survives falls from 6–8 feet.

- Battery Options: Long life and warranty.

- Construction: Rugged, heat-resistant housing with glove-friendly controls.

Conclusion

Durability in thermal imagers is essential for operational reliability, safety, and long-term value. By focusing on real-world performance, verified testing standards, and feedback from trusted sources, you can choose a device built to meet the demands of the fireground. Regular maintenance, strong warranties, and modular designs further enhance the longevity of your equipment, helping it to remain a dependable tool when it’s needed most.